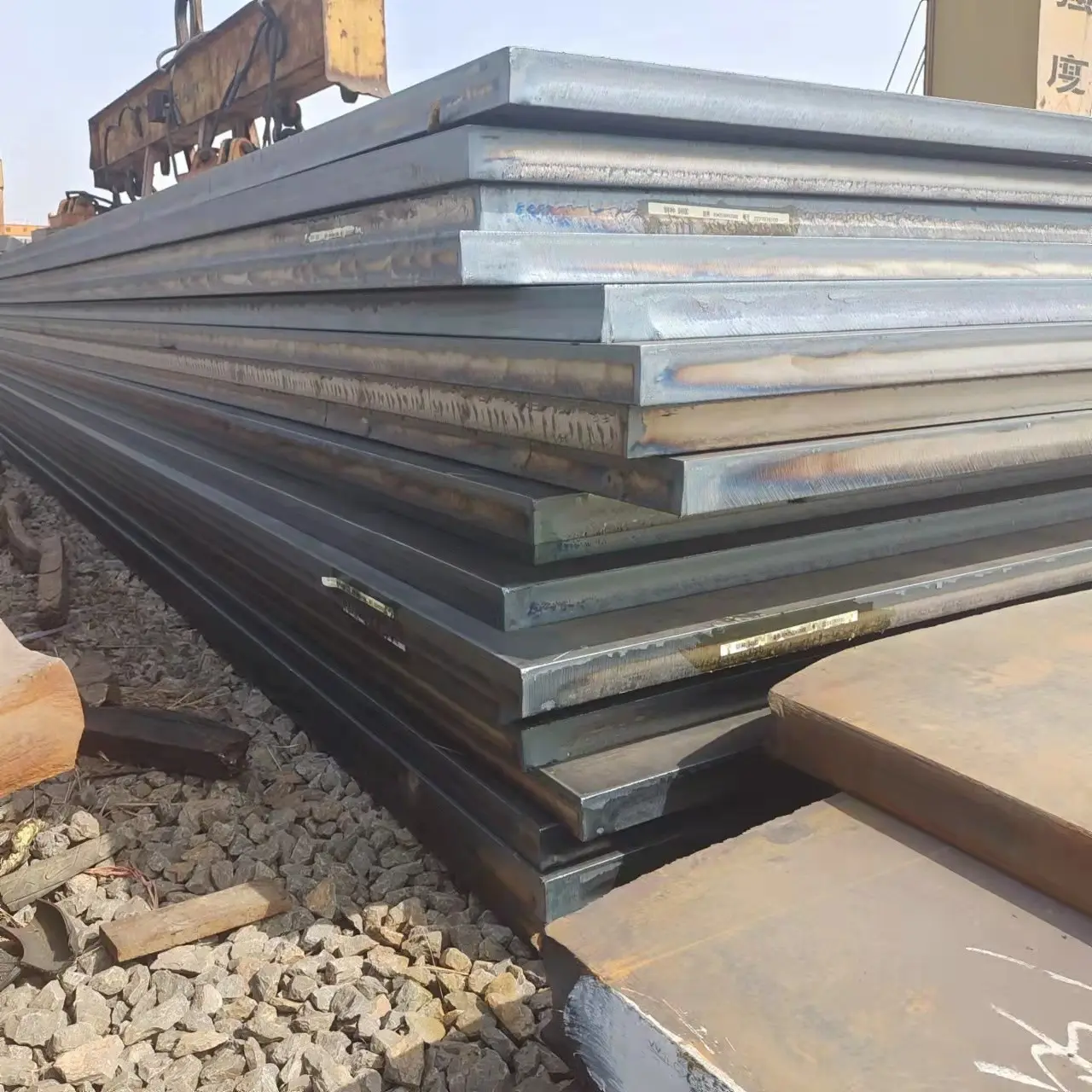

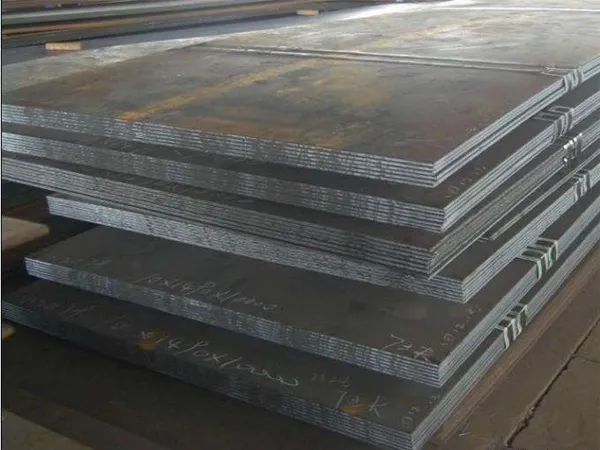

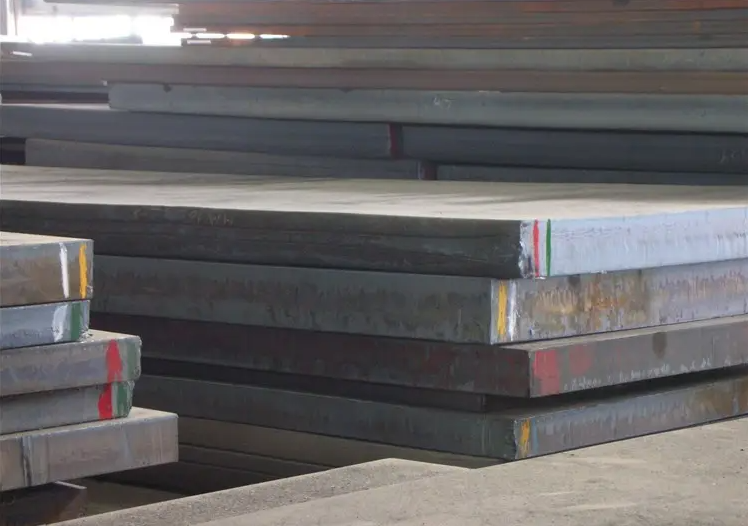

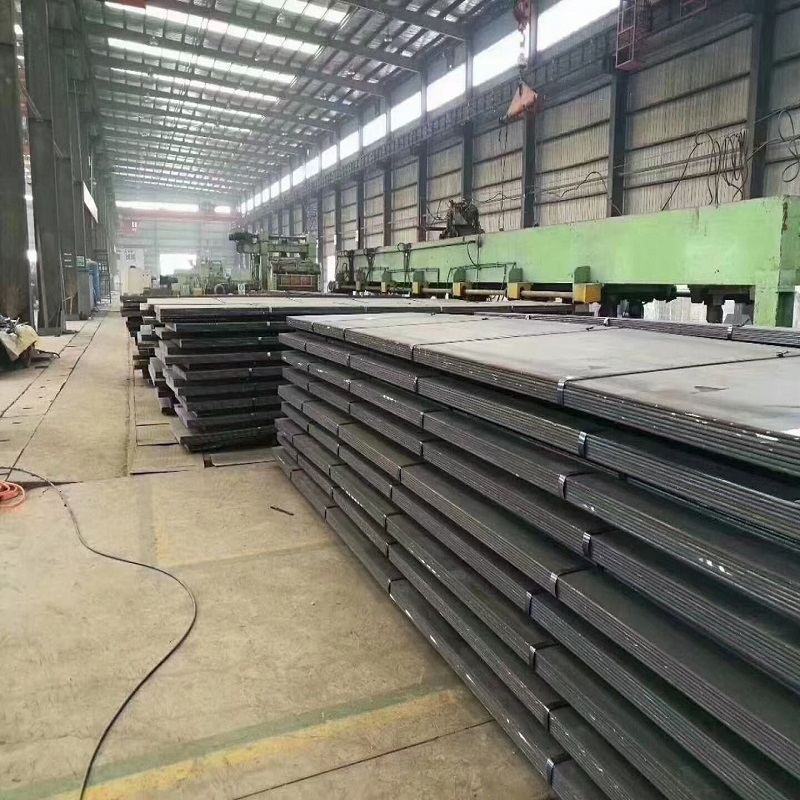

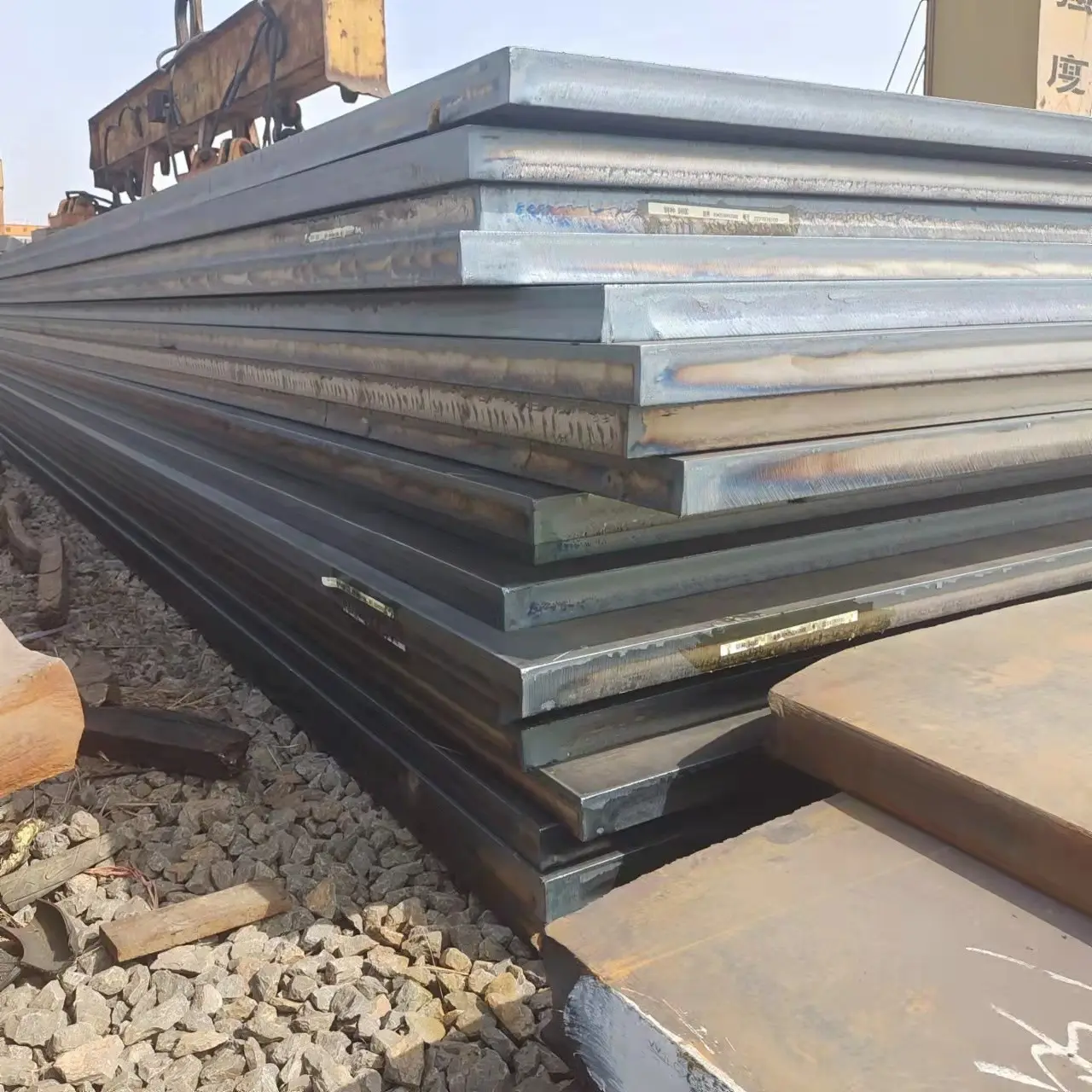

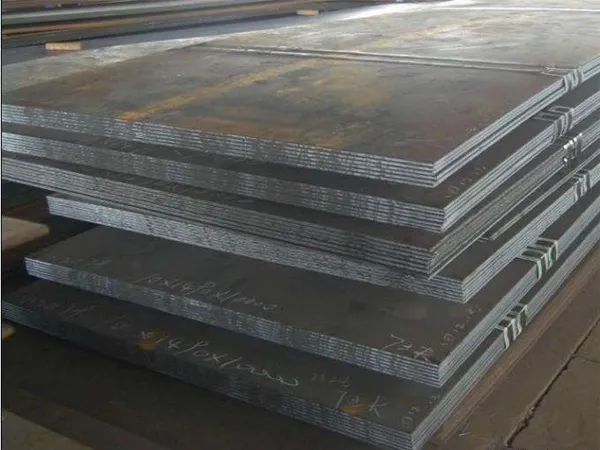

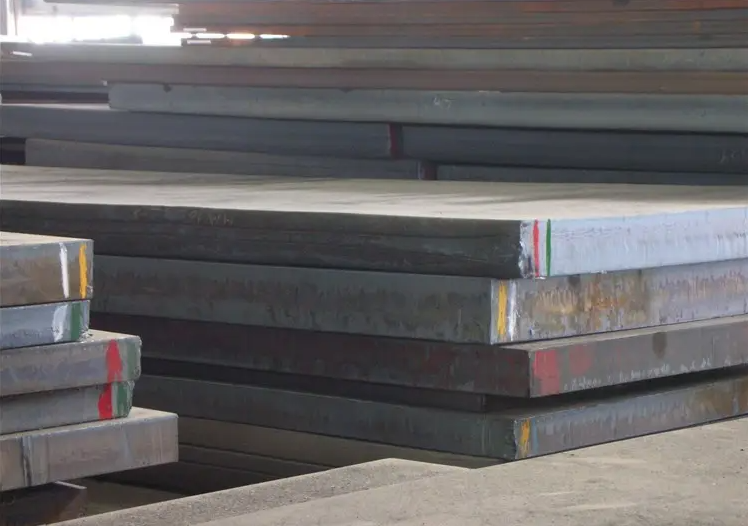

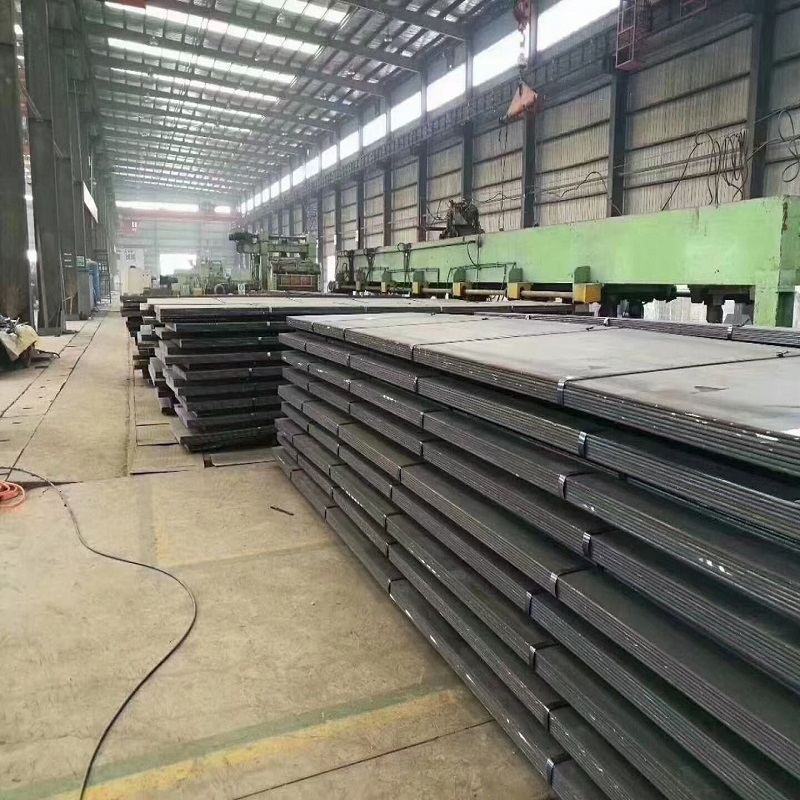

Glavni materiali so visokokakovostno konstrukcijsko jeklo in jeklo z nizkim zlitinom. Jeklo, ki se pogosto uporablja, je jeklo z nizko vsebnostjo ogljika, ki ga je talil z odprtim ognjiščem ali nizkoogljičnim jeklom, ki ga je talil z električno pečjo. Vsebnost ogljika WC je v območju od 0,16%-0,26%. Ker je jeklena plošča kotla deluje pod visokim tlakom pri srednji temperaturi (pod 350 ° C), poleg visokega tlaka pa je podvržena tudi udarcu, obremenitvi utrujenosti in koroziji z vodo in plinom. Zahteve glede zmogljivosti za jeklo kotlov so predvsem dobro varjenje in hladno upogibanje. Zmogljivost, določena visoka temperaturna trdnost in alkalna korozijska odpornost, oksidacijska odpornost itd. Jeklene plošče kotla običajno delujejo v srednjih in visokih temperaturnih in visokih tlačnih pogojih. Poleg visoke temperature in tlaka so podvrženi tudi obremenitvam utrujenosti in koroziji z vodo in plinom. Delovni pogoji so slabi. Zato morajo biti kotlovne jeklene plošče dobre fizične in mehanske lastnosti. Obdelovalnost za zagotovitev varnosti uporabe opreme

Glavni namen

Široko se uporablja v naftnih, kemičnih, elektrarnah, kotlu in drugih panogah, ki se uporabljajo za izdelavo reaktorjev, toplotnih izmenjevalnikov, ločevalcev, sferičnih rezervoarjev, rezervoarjev za nafto in plina, rezervoarji za utekočinjene pline, lupine za jedrsko reaktor